Tips for Maintaining Your Industrial Boiler

When you're running a facility, you understand that each piece of machinery plays an important role. Even if a small amount of the automated system crashes, the whole manufacturing system will come to a halt in the manufacturing segment. The industrial boilers may seem like a distant fit, but it is one of the most critical components of the industrial set up. Best practice to extend the performance and longevity of your boiler is annual commercial boiler repair and maintenance from boiler professionals to ensure smooth operation for many years.

Here are a few tips that can help you with the optimum usage of the boiler.

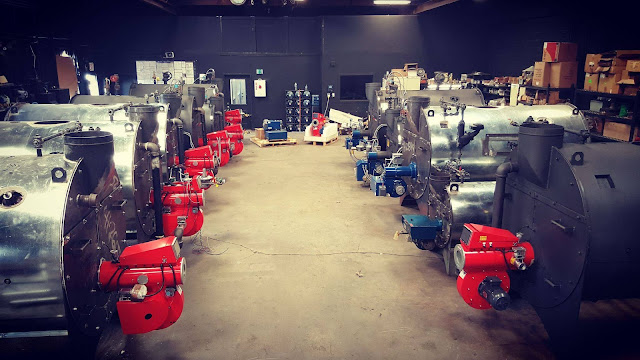

Fuel upkeep: it is essential to maintain the amount of fuel in the industrial boiler. An optimum input and output of energy means you're maximizing your boiler performance without wasting extra energy. It will also give you the additional benefit of keeping the overall fuel cost down for the boiler. You should appoint a person for a routine check-up of the boiler and fuel maintenance. In addition to this, one must also keep a check on the burner maintenance and cleaning. With a steady flame from the burner, the fuel consumption will remain low, and the boiler will work well.

Cleaning the boiler: While we recommend periodically cleaning the various parts of the boiler, the water gauge glass holds more importance. As the name suggests, the glass shows the level of water in the boiler. With constant usage, this glass may become cloudy or have calcium deposits on the surface. It makes the process of reading the water level quite tricky. On some occasions, you may have to replace the glass when the boiler is not working. It generally happens when the glass cannot be cleaned any further and is still disrupting the process of reading. These small investments may seem tedious, but they are manageable tasks that make a huge difference to prevent major boiler failure.

The operator should also ensure that they clean the water float from any sedimentation that may have taken place over time. The water level control feature on a boiler plays a critical role in energy output, so any build up will cause the boiler to run not as efficiently. This part should also regularly be cleaned for any sludge or sedimentation in the control feature.

Monitor the temperature gauge readings: In specific industrial setups, people install the stack temperature gauge to check the level of fuel that leaves the system. It may not seem important at first, but the operators should monitor the reading over time. A high-temperature reading indicates that there is soot and other deposits in the tubes that will continue to hinder optimal performance if not cleaned in time. Experts suggest that high reading may also indicate baffling inside the boiler that might have burned or deteriorated, therefore allowing some of the hot gas to bypass the heat transfer surfaces. You can make the required changes and alterations in the boiler once the system is under maintenance to get things back in order.

Keeping a boiler log: A diligent operator should always keep a boiler log that tracks the boiler's history in performance failure and what services were performed to fix it. It helps in the smooth operation, maintenance, and testing of the system. When you look at the deterioration of the numbers from the sample timings, it indicates scheduling a gas boiler maintenance. This will help you inform the staff beforehand so that they come up to speed with the work and there is no loss in productivity of the whole unit. If you do not maintain these logs, you may not notice the small indicative changes that can cost you a lot in the future.

Comments

Post a Comment