Gas Boiler Maintenance Tips for Optimized Performance All Year

Gas boilers are the primary source of energy that powers heavy machinery with high pressure, low-pressure steam or hot water. The benefits of investing in a gas boiler include the abundance of natural gas to convert into usable energy and the high energy-to-heat ratio. Boiler run times are dependent on production needs, but the winter season tends to demand higher energy outputs due to several external factors. Primarily, the colder temperatures make it more difficult to re-commission the gas boiler and requires more energy.

With proper gas boiler maintenance, it's possible to keep utility and service costs at bay. Perform these maintenance tasks year-round so you can maintain optimal performance even throughout the winter months.

Gas Boiler Maintenance Best Practices

For maximum boiler efficiency and a hassle-free winter, we have curated some easy and dependable tips for you to follow.

Monitor the gauges and controls - Never use your gas boiler more than required. Check the gauges and controls to monitor performance output. If you're noticing that it requires more energy to convert usable energy, this indicates that there's something wrong with your boiler system. Over-compensating for possible leaks, cracks and breakages can lead to irreversible damage to your gas boiler. Seek a boiler technician to service the boiler immediately if you aren't able to identify the issue.

Schedule routine boiler inspections - Even if your boiler is working well, make a habit of getting it checked and serviced annually, at least. Boiler professionals can identify and replace boiler accessories that enhance your gas boiler's performance. Also, they ensure that the boiler is still safe to operate and is properly burning the fuel without creating carbon monoxide. Boiler inspections benefit performance and help you maintain a safe environment for your facility.

It's time to replace the gas boiler - It's natural to be hesitant when it comes to replacing cherished items. However, if your boiler has been in commission for 10-15 years and requires servicing more often, then it's time to let it go. We encourage owners to replace their gas boiler sooner as a predictive measure, rather than later which results in complete boiler failure. What's great about newer boiler models is the ease of controls and cutting-edge technology to reduce carbon emissions.

Invest in boiler repair services - Major damages like pipe and valve leaks require a boiler professional to repair. They will have the necessary tools and knowledge to fix it as a long-term solution. Don't put your facility at risk with DIY remedies. Rely on McKenna Boiler who can send a technician to service any boiler type in no time.

Drain and vent the pipes - Upon decommissioning your boiler at the end of the day, make sure to drain the pipes for the water to escape. Water present in pipes for extended periods of time can create mineral scale and build-up which affects boiler performance. Additionally, colder temperatures will freeze the water which will expand in the pipes. This can lead to leaks and breaks, serving as a major hindrance to your production schedule.

How does McKenna Boiler Optimize Gas Boiler Performance?

For all your gas boiler maintenance needs, McKenna Boiler offers turnkey solutions for boiler rental, maintenance and repair services. We approach consultations with a solution-oriented mindset by connecting you with our expert team in no time.

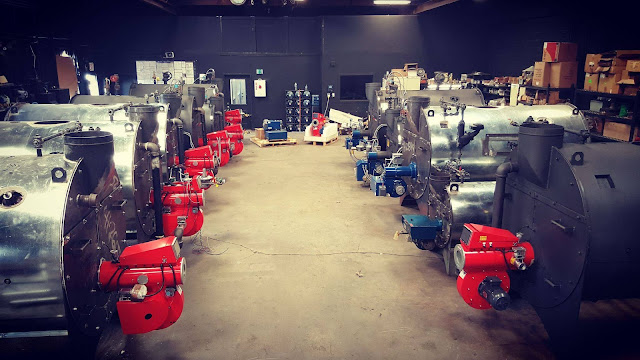

Explore our wide range of boiler units, accessories and systems. We even have a special line of low NOx boilers that are certified as environmentally friendly and reliable to provide clean fuel-burning and efficient heating. Our boilers are designed and stamped according to the latest ASME codes and are inspected and registered with the National Board of Boiler and Pressure Vessel Inspector.

The products are delivered on time and installation assistance is provided. McKenna Boiler is always ready with its inspection and servicing facilities and in case your boiler is giving you a difficult time, we are here to help you repair or replace it so you can resume production immediately.

Comments

Post a Comment