Improve Steam Boiler Efficiency with Feedwater Systems in Your Facility

A facility's industrial boiler is one such machinery that needs close attention like routine inspection and maintenance, considering the fact that it supports several operations and is a key component in the production cycle. With several operations running on a single machine, one of the easiest ways a business can reduce operating costs is by increasing the efficiency of their high-pressure boilers. But how can business owners achieve this?

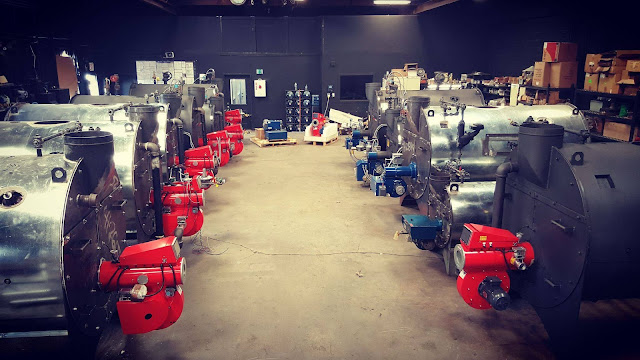

The best time to examine areas to minimize utility costs and increase your efficiency in demanding work environments is during boiler maintenance and inspection performed by a boiler company like McKenna Boiler. Our boiler services offer an extensive inspection of your entire boiler system with the right boiler product or boiler accessories to optimize your boiler's performance. If you have a hard time meeting production goals during peak season, then consider integrating feedwater systems into your boiler system to maintain and improve boiler efficiency year-round, and most importantly peak season.

Before we get to our efficiency tips, here is how boiler efficiency works. Changes in the temperature, pressure, and flow rate can affect functioning and efficiency. The goal is to create conditions that increase the efficiency and the facility ends up with the smallest possible amount of fuel gas at the lowest possible temperature. For high-pressure boilers to produce proper steam, a feedwater system is a necessary component that can vastly improve the entire boiler system.

What do feedwater systems do?

How does a boiler feedwater system assist your boiler? In simple terms, the feedwater system is built with durable carbon or stainless steel tanks that collect and reheat the return condensate from the steam system. This technique is implemented before problems such as fouling, scaling, and corrosion occurs which can go a long way in avoiding costly maintenance or replacements on the boiler system down the line.

To add to the process, the returned condensate is then mixed with softened water that is technically treated to remove the oxygen, carbon-di-oxide, and other non-condensible gases from the water mixture before it is pumped into the boiler.

The reason you need a feedwater system is to keep the boiler in your facility free from corroding carbon steel piping and steam traps. Corrosion and deterioration occur due to oxidation, so minimizing the amount of oxygen present in the boiler system through the feedwater system is imperative for protecting the interior piping. While you may think of these concerns as long-term maintenance tasks, it's important to routinely inspect your pipes for leaks, breakage, and corrosion to ensure maximum productivity without putting your industrial boiler at risk. Moreover, it is important to remember the repairs can take time, depending on the size of the boiler. So to avoid such circumstances, it is best to invest in feedwater systems supplied by McKenna Boiler that will optimize your boiler system in demanding work environments. Our feedwater systems will prolong the life-cycle of your high-pressure boilers by providing storage for water make-up and return condensate to avoid corrosion from the system loop. That's why this is such an indispensable part of system care and reliability.

Feed pumps are designed to handle the amount of pressure your facility needs

Boiler feedwater pumps to transport water into the boilers using high temperature. To improve efficiency, it is important to maintain the standard of all inputs of that system.

To ensure that it is good to handle, it is important to check the pressure and temperature regularly. To make it easy for you and avoid downtime, along with regular maintenance, test boiler feed water and condensate return weekly or every 15 days for dissolved oxygen and total dissolved solids.

Comments

Post a Comment