Tips to Optimize Your Industrial Boiler Performance

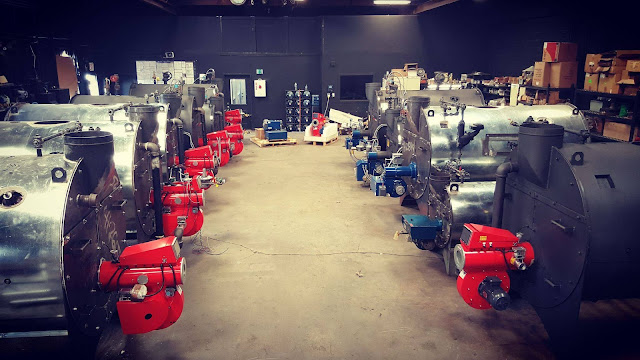

There are many steps in the production process every business owner should be aware of to ensure the success of their business enterprise. The appliances and technical setup should run at their full capacity for a high return on investment. Most industries that deal with mass production require the use of the industrial boiler. They are typically used for energy production by steam for manufacturing the desired products. Pressure vessels, such as industrial boilers, can be sensitive to various scaling and heat loss issues if they are not properly maintained.

When a device or appliance malfunctions in an industrial setup, it can do more damage than you can imagine. The energy intake increases, which can trip the electricity supply, and halt the whole production line for extended periods of time. . It can also be hazardous for the employees if it does not run appropriately. The best way to ensure your industrial boiler is working properly is by performing routine maintenance and getting it serviced by a professional boiler company that can set you up for success at the initial installation process.

The experts from boiler installation services share a few tips and tricks that can help you reach break-even on your boiler investment quickly.

Cleaning the Boiler Periodically:

An industrial production setting calls for extensive workloads on machinery. Industrial boilers are built keeping the same in mind. However, water and dust can seriously affect your boiler's critical points of performance. . When you work with a boiler installation company, they can help you with further maintenance and cleaning work. The experts suggest that a coating of residue as little as 0.03 – 0.05 inches thick can reduce heat transfer by upwards of 10%. Ultimately, this affects your energy production intake and output, thus determining your boiler as inefficient. Hence, cleaning the boiler annually can help you with the boiler's long life in your setup.

Reduce Boiler Blowdown:

When the boiler runs endlessly for every few hours in a day, the total dissolved units in the boiler can cause the matter to solidify which causes hardening and build upon the inside surface of the boiler pipes. If you ignore this for a long time, it will hinder proper transportation within the pipes and lead to major issues like complete boiler failure. . When you regularly drain the water from the blowdown, you can increase the boiler's life and give it a rest period as well. You can easily do this with the help of professional boiler installation services.

Monitor and Manage Water Quality:

When you eat well, your body will respond similarly. The machinery operates on the same principle. What goes in the machinery will have a high impact on the level of endurance and functionality. When we talk about the boiler, the amount and quality of water that goes into making steam will affect the product's overall performance. Even though it is challenging to check on these little details when you have a large-scale setup, you can always split up the responsibilities and alternate days to get the proper tasks done. When your business operations heavily rely on boiler energy,, regular checks/testing of dissolved minerals, returned condensate, and the presence of a de-aerator are essential. You can take help from the boiler installation company for these checks from time to time.

Inspect Insulation:

Boiler professionals install boilers with weather conditions in mind to account for different environments the boiler will be operating under. For those who are new to the industry setup, it is essential to check on the insulation of any surface that will go above 130-degree Fahrenheit while working. Despite the industrial boiler brand, you must check the insulation level at regular intervals to prevent any malfunctioning.

The best way to deal with these heavy-duty machineries in the industries to keep a maintenance log of various aspects. Documenting the status of your boiler will come in handy when it comes time for the annual maintenance check-up with a professional. They'll be able to review your log and suggest preventative methods to help you extend your boiler's lifespan.

Comments

Post a Comment